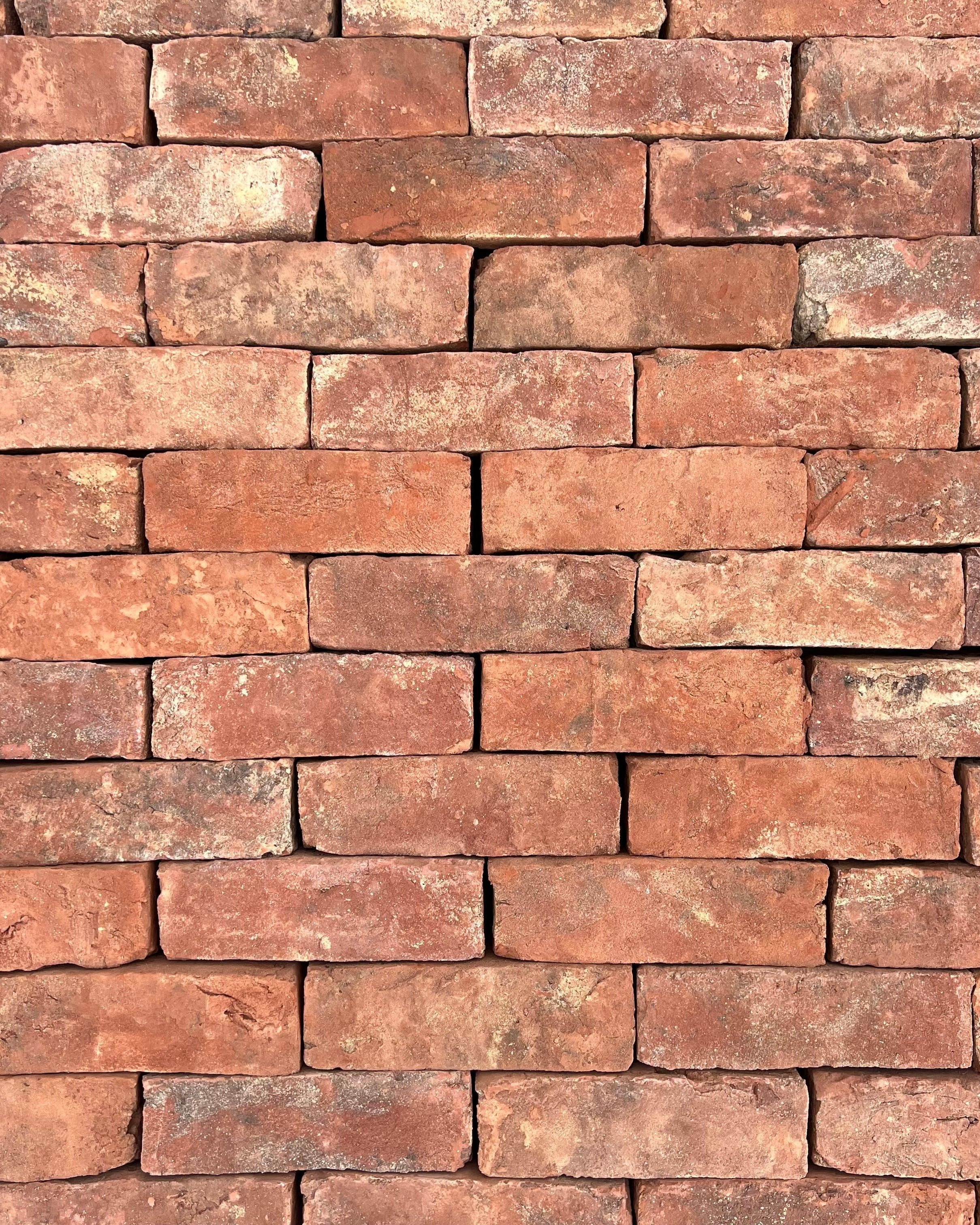

Traditional Clay Pavers, also known as brick pavers, are a popular landscaping material choice for landscape gardeners, architects, garden designers, and builders, due to their beauty, versatility and strength. Our stylish landscaping product range are crafted from natural clay and fired up to 1450 degrees in purpose built kilns over a period of eight weeks. Brick pavers are one of the most common natural paving materials within the UK and Europe, cherished due to their rich long-lasting colour, durability, stain resistant properties and minimal maintenance requirements.

Clay pavers can be used for both residential and commercial purposes, having a wide range of uses. Some of the more common applications include:

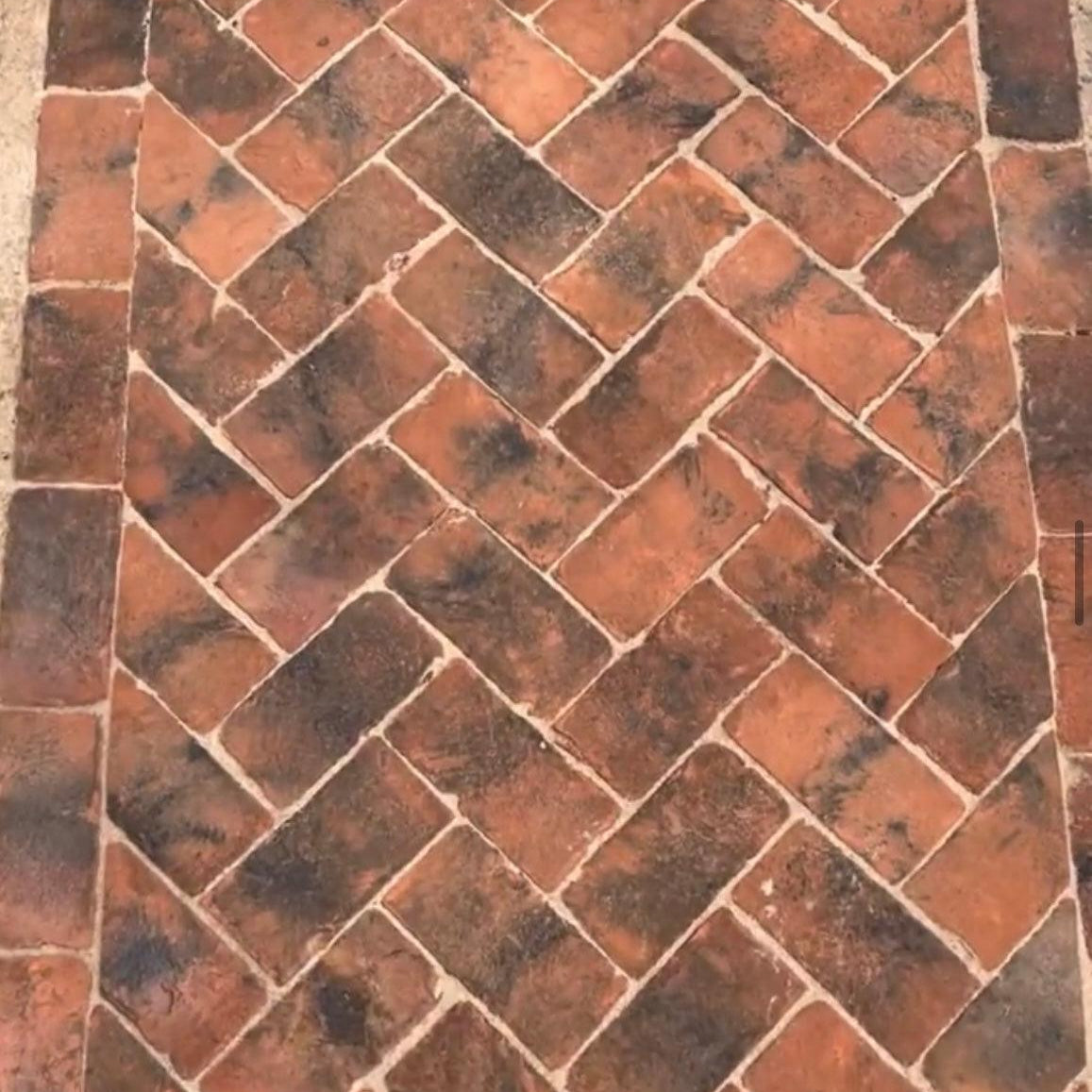

Patios – clay bricks add serenity and movement to terraces and can be combined with other paving types to provide a stunning finish.

Driveways – clay paving is an excellent choice of paving for use on a driveway, providing kerb appeal and a robust base for your vehicles.

Pathways and Borders – due to their convenient brick sizing, clay pavers are a versatile paving material that lends itself beautifully to being used in paths.

Steps and Entranceways – using clay paving bricks in your front garden can provide a timeless, beautiful welcome to homeowners and guests alike.

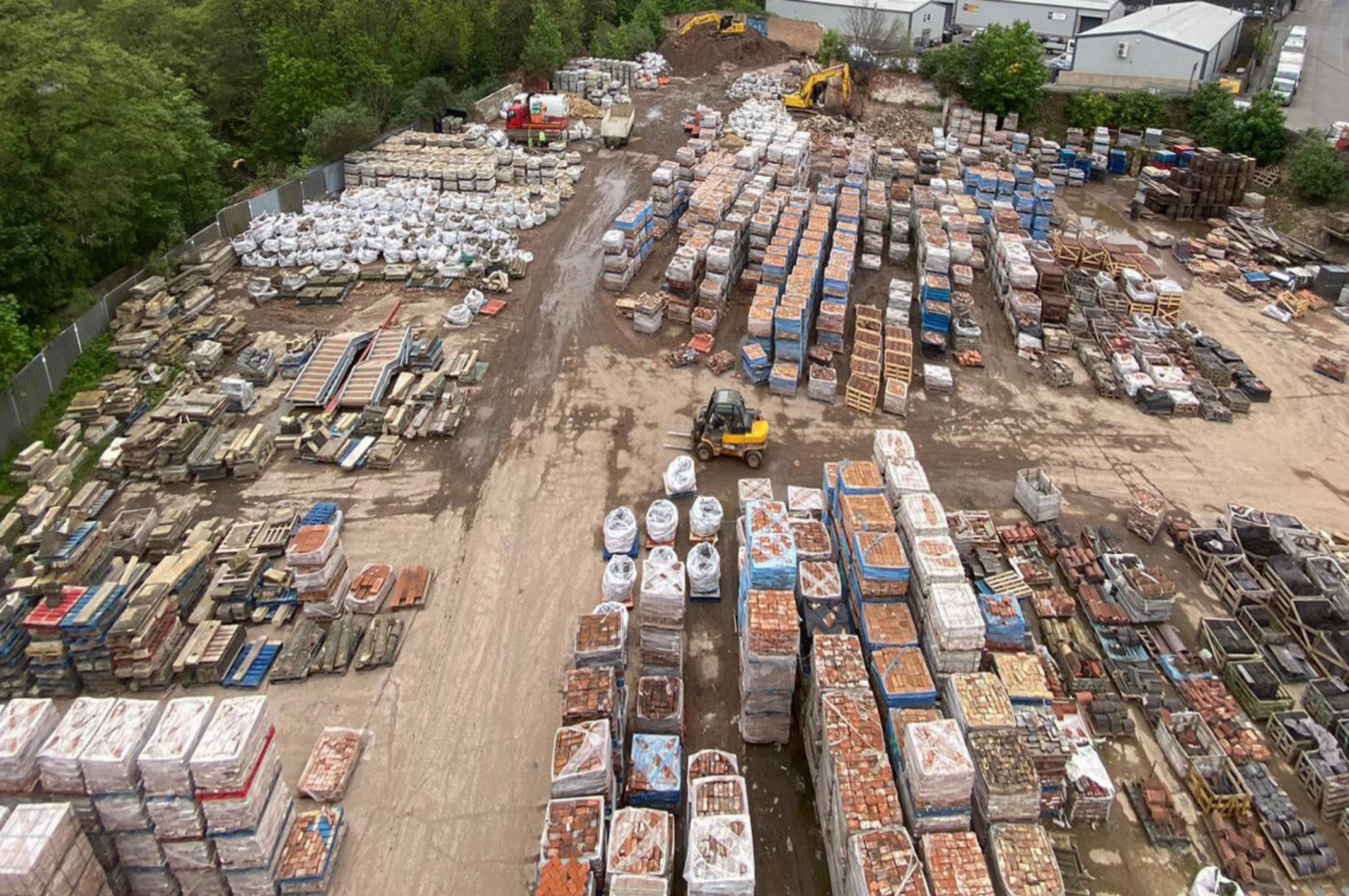

Heritage Brick Company are proud to being to market a complete range of natural clay landscaping products that have been design with quality and traditions in mind - A Passion For Clay.

Shop Paving Bricks

Clay Pavers

The Traditional Handmade Clay Pavers is the ideal choice for your domestic landscaping project. Whether you're designing driveways, pathways, edgings, or gardens, our clay pavers provide both durability and aesthetic appeal.

With a wide selection of colours, from warm terracotta to mellow pinks and weathered yellows, you're sure to find the perfect match to complement your outdoor space. These pavers offer long-lasting quality and timeless charm, making them the perfect solution for any landscape design.

Dutch Stacker

Dutch Clay Stackers can add a true sense of authenticity and class to any patio, pathway or drive, this paving products work in both contemporary and traditional setting and can be laid in a wide range of interesting patterns. Clay pavers are a truly versatile product allowing the creation of many geometric designs and curves without the need for extensive cutting or difficult laying techniques.

These Dutch Clay Pavers have a tumbled edge with a sanded face for a unique and distinctive surface finish, the tumbling process means these products will contain small chips on all edges.

Machine Pavers

Machine made clay pavers are an excellent paving material suitable for a vast range of landscaping installations. These brick pavers have been used for centuries across Europe and have proven to be a versatile and attractive product for both commercial and domestic landscaping applications.

Brick Steps

Clay fire brick pavers are a great choice for steps due to their convenient brick sizing, durable properties and rough anti slip texture. Clay bricks are a versatile paving material that lends itself beautifully to being used in garden steps and paths.

Brick Edging

Garden edging is often over looked in garden designs but plays a key role in framing features within a garden such as patios, paths and flower beds. Due to their durable properties and contrasting colours, bricks are great option and to provide a long lasting garden boundary edging.

Garden Walls

Brick walls provide a wide range of benefits in garden landscaping design. They not only offer privacy and security but their attractive aesthetic appeal creates a backdrop of natural colours to frame a garden design. The warm red tones or yellow hues of the Heritage Brick Range are a great brick choice for brick walls in landscape garden design.

Benefits of Brick Pavers in Landscape Design

Weather Resistant

Our range of specialist designed Clay Pavers achieve a frost rating of FP100, by only using selected clays and sand, and fired at a higher temperature for longer periods than most facing bricks. They are specifically designed to withstand saturated freeze / thaw cycles.

Natural Material

Keeping true to our beliefs and traditions of British landscaping materials, our landscaping products are manufactured from the highest quality natural clay. Offering a natural and charming appearance to any garden design.

Simple to Install

Our range of landscaping clay products are convenient sized and consistent making them a breeze to lay. They can be installed onto kiln dried sand or wet cement for a long lasting setting. Clay pavers can be used for both residential and commercial purposes, having a wide range of uses.

Garden Design & Brick Landscaping FAQs

Can clay bricks be laid in the ground?

Yes, clay bricks can be laid in the ground, but there are some things to consider:

- Preparation - Before laying clay bricks, you should prepare the ground with a sub-grade or sub-base. You can also install edge restraints, such as a pre-cast concrete kerbstone.

- Bedding course - Lay a bedding course of moist grit sand that's 40–50 mm thick. The sand should be able to hold its shape when you squeeze it in your hand. Compact the sand and screed it to level the surface.

- Drainage - To improve drainage and prevent weeds, you can install a geotextile fabric before laying brick pavers.

- Edge restraint - Make sure the edge restraint contains both the brick paving and the sand bedding layer. This will help prevent the paved area from subsiding

Are clay pavers frost proof?

Yes, clay pavers are frost resistant:

- Fired at higher temperatures - Clay pavers are fired at a higher temperature and for longer than most facing bricks, making them more frost resistant.

- Durable - Clay pavers are hardwearing and can resist salt and freezing better than concrete pavers.

- Slip-resistant - Clay pavers don't polish to a smooth surface, so they maintain good slip resistance.

- Low maintenance - Clay pavers are low maintenance and can last a long time.

- Environmentally friendly - Clay pavers are made from clay, sand, and water, and can be reused or crushed into aggregate.

Clay pavers are a good choice for outdoor paving in the UK, where you can expect heavy rains and snowfall.

Do clay bricks absorb water?

Due to the high temperatures our range of clay pavers are produced they have a very low water absorption and are fade resistance and naturally low maintenance. If you’re looking for a durable, beautiful product that will enhance your home and garden, and that will look great for many decades to come, look no further than Genuine Clay Pavers from Heritage Brick Company.

Can Clay Pavers be used for drives?

Hard wearing and durable these clay pavers are ideal in high traffic domestic and light commercial settings, with a life expectance over 100 years you can see why Heritage Clay Pavers are fast being a popular product across UK.

Do clay paving bricks have to be sealed?

Whether or not to seal clay pavers depends on your preferences and needs. Some say sealing is not recommended because clay pavers are designed to resist staining, and oil usually sits on the surface of the stone. However, others say sealing can provide added protection and easier maintenance. Here are some things to consider when deciding whether to seal clay pavers:

- Appearance: Sealing can enhance the appearance of your pavers, but it can also darken them. You can test the effect of a sealer on a sample piece before applying it to your pavers.

- Maintenance: Sealing can make pavers easier to maintain.

- Breathability: Sealing can restrict the breathability of your pavers.

- Protection: Sealing can protect against weeds growing through the joints and prevent sand loss.

- Water absorption: Clay pavers are porous and can absorb water and oil, which can lead to staining if not sealed.

- Sealant type: Choose a high-quality sealant designed for clay pavers. Solvent-based polyurethane sealers are a good option because they last longer and hold a gloss look well.

- Application: Ideally, you should seal before pointing, but it's not the end of the world if you seal after. Natural stone sealant works best in dry, warm conditions.

How to maintain brick paving?

Here are some tips for maintaining brick paving:

- Replace broken pavers - Broken or uneven pavers can collect dirt, debris, and standing water, which can be dangerous.

- Clean regularly - Regular cleaning keeps brick looking fresh and new, and extends its lifespan. You can clean with a mixture of warm water and a gentle household cleaner, like dishwashing liquid. You can also use a low-pressure power washer for stuck-on gunk, but avoid aiming it between pavers.

- Remove weeds - Weeds can grow into the bricks and damage them. Gently pull weeds out between the paver joints, then brush off any debris. You can also use herbicides or fungicides to prevent weeds, moss, or algae from growing.

- Maintain drainage - Ensure that your storm water drains are clear and run water away from the paved area.

- Top up jointing sand - If you remove a lot of underlying sand by pulling weeds, you may need to re-sand your pavers.

- Remove stains - For oil stains, sprinkle baking soda or cat litter on the area and let it absorb the oil. After a few hours, sweep or vacuum the residue.

What sub-base to lay paving bricks on?

When laying paving bricks, you can use a sub-base ofhardcore, sand blinding, or MOT Type 1:

- Hardcore: A common choice, made of broken concrete, stone, or bricks. It's important to compact it well to create a stable base.

- Sand blinding: A less common option, made of a thin layer of sand. It's often used with hardcore to create a level surface.

- MOT Type 1: A high-quality option made of crushed granite, concrete, or limestone. It's permeable, which allows some water to pass through.

The sub-base should be at least 100 mm deep to support the weight of people and vehicles. You can apply the sub-base in layers, compacting each layer with a compactor. It's important to compact the sub-base well to avoid an uneven finish. You can also use mortar, pedestals, or bituminous material under pavers. The mortar set method is popular for areas that need a rigid system, such as pedestrian or vehicular areas.

How to joint clay brick pavers?

To joint clay brick pavers, you can:

1. Brush in sand: After laying the pavers, brush fine, dry kiln-dried silica sand into the joints until they are full. You can use crushed sand that's 2–4 mm in grade.

2. Compact: Use a vibrating plate compactor with a rubber soleplate to compact the pavers into place.

3. Repeat: Repeat the process of brushing in sand and compacting until the joints are full.

4. Spread sand: After the final compaction, spread 1–2 mm of sand over the area to fill voids and promote joint fitting.

Here are some tips for working with clay brick pavers:

- Check the pattern: Use string lines to check the pattern of the pavers and adjust as needed.

- Start at the bottom: If you're working on a slope, start at the bottom and work your way up.

- Use a disc cutter: If you need to cut pavers to fit, use a disc cutter to make accurate cuts.

- Allow time to seal: Let the jointing sand seal in for at least 6–8 weeks before cleaning the surface.

- Avoid high pressure washing: High pressure washing can remove the jointing sand and weaken the surface.

- Use a joint stabilizer: If you use a flexible construction method, you can apply a joint stabilizer to prevent the jointing sand from eroding.

Can I order Clay Paver Samples?

Order via Product Page

On the specific product page, to the right of the product image there is an 'Order Sample' Button. Click the button to order your sample online.

Order via Email

Simply email our sales team your project requirements and specific product you wish to order a sample.

Visit Us

If you are close by or wish to see our full range, why not come and visit us at our bespoke Brick Centre? and take samples away free of charge.

Download the Brick Catalogue

Our catalogue of curated traditional clay bricks contains the latest collection of colours and textures, produced using modern machinery and traditional manufacturing methods.