Our carefully curated range of roofing tiles and slates are specially selected to complement our Heritage Bricks. Our roof product offering includes handmade tiles, machine made clay roof tiles, pan tiles and accompanying roof fittings. Only available in natural clay colours originally quarried from the earth; our products have natural variations in shape texture which will furnish your build with a traditional, established look.

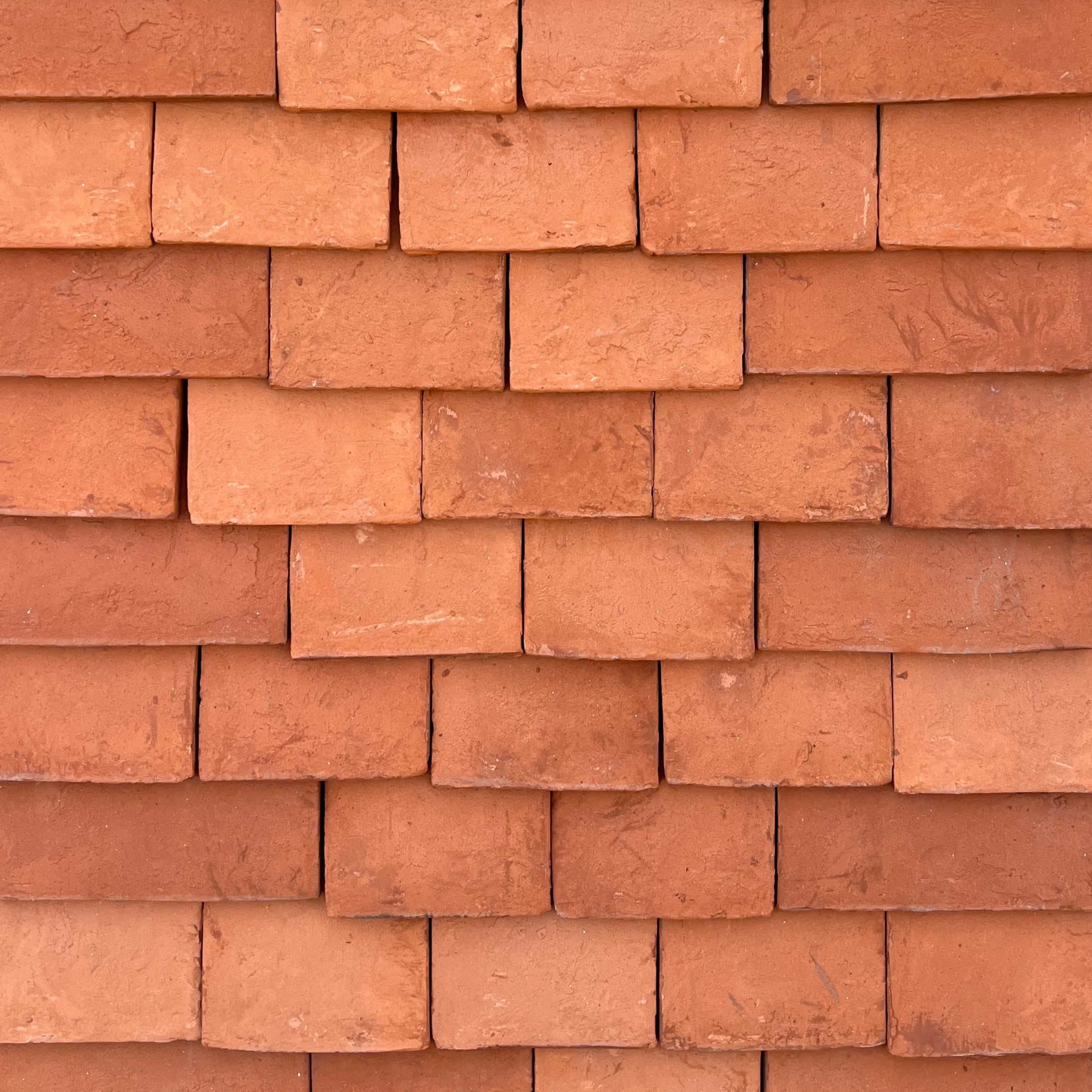

Each Heritage Tile is genuinely crafted by hands of skilled artisans. Gifting each tile with its own individual character and perfect imperfections, including the makers’ fingerprints. Each worker makes around 800 tiles per day. After the making process, the tiles then go into the drying room where they are dried to bring them to below 5% moisture. Once this process is complete, the tiles are ready for firing. The main benefit of crafting each tile by hand is the outstanding aesthetics that come along with it. It is our belief that uniformity in tiles doesn’t allow a roof to stand out as it should. After all, the roof is one of the main focal points when you first notice a property. Nothing makes a roof stand out from the crowd like a genuine handmade clay roof tile.

Shop Handmade Clay Roof Tiles

Handmade Roof Tiles

The finest clay roof tiles, handmade using traditional English methods. These beautiful clay tiles offer individuality in appearance and blend together to recreate the look of yesteryear. Their timeless nature and enduring quality makes them equally well suited for new build, renovation or restoration projects. Our variety of carefully selected blends provides an ideal match for all architectural styles and personal tastes.

Available in a range of timeless colours that offer an established, characterful look which will retain for decades to come.

Machine Roof Tiles

Machine made roof tiles provides the consistency of a tile made from very fine clay in state-of-the-art production facilities. Its wide range of colours guarantees that machine roof tiles will blend with contemporary residences just as well as with more traditional homes, maintaining every construction’s own identity.

Clay Pantiles

Clay Pantiles, also known as S-shaped tiles, are machine made and hand finished, combining the benefits of both. The Heritage Clay pantile offers individuality in appearance created by hand finishing while retaining the economic and quality advantages associated with machine made pantiles. Their timeless nature and lasting quality mean the heritage clay pantiles are an ideal solution for new build, renovation or restoration projects.

Roof Fitting Specials

With every good design – the true skill in completing and enhancing a stunning building project or development is the finishing touches.

Our handmade range of clay fittings are not only a natural choice in conservation areas but will add to the character and value of any property.

From valley tiles to ridge tiles and with the addition of bespoke individually crafted products including mono, third round & baby porch ridges, vented ridge tiles, bat access tile sets, plus ornamental tiles – club, bullnose, diamond and fishtail.

Bespoke Roof Features

We offers a wide range of bespoke and non-standard peg and plain clay roof tiles designed to match the varied sizing requirements of old and historic buildings in order to help renovators replicate and preserve the architectural integrity and original character of older properties.

These individual sizes and shapes can also be tailored to modern specifications in order to make new build projects truly unique.

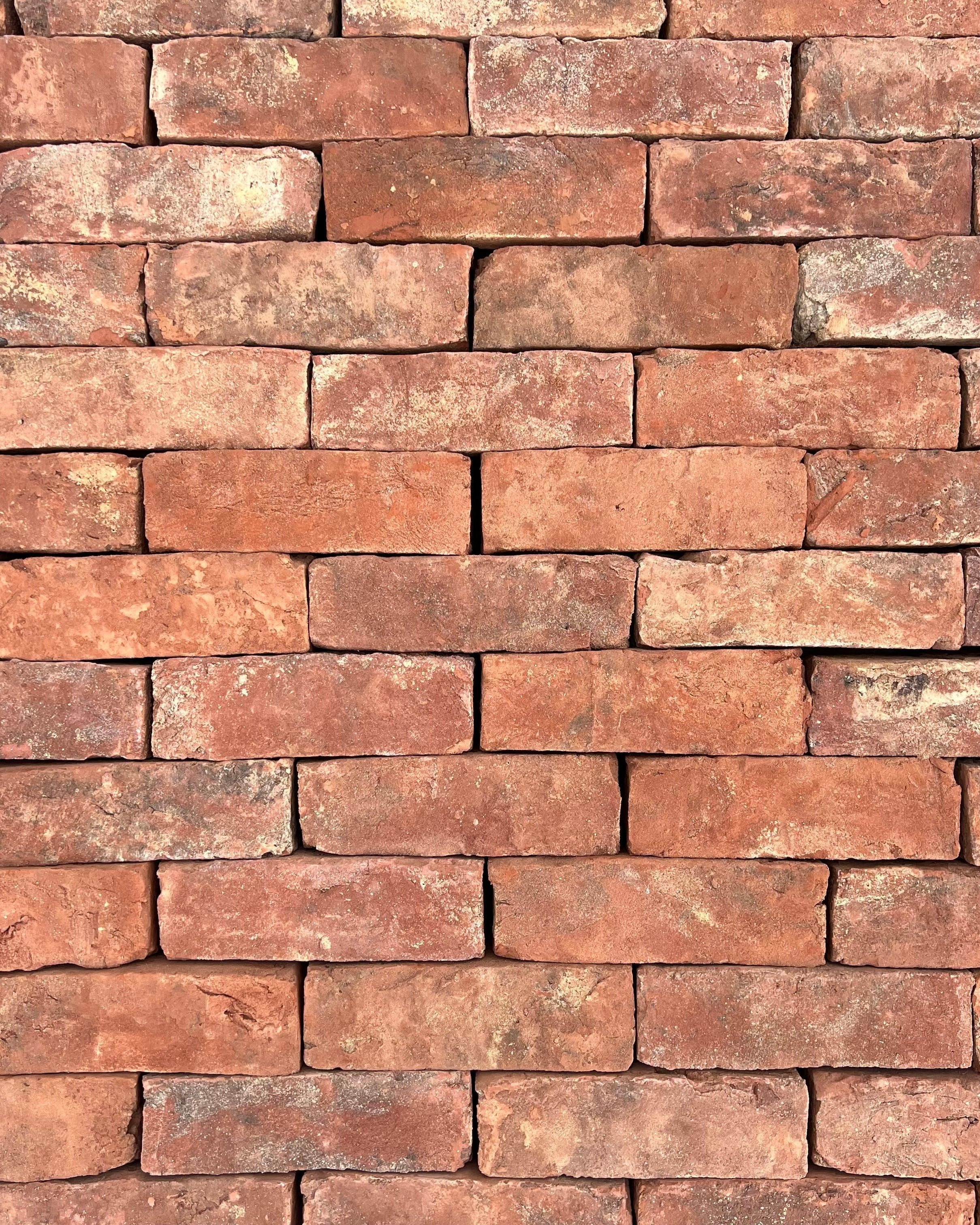

How Brick Weathering can help?

Lifetime Guarantee

Each tile is crafted, produced and tested to last a lifetime, and invariably much longer. Most are guaranteed for 30 years. Whether a homeowner requiring expert advice, an architect or developer creating distinctive homes to which buyers aspire, or a builder or roofing contractor seeking exceptional products and service, we have all that you need.

Simple to Install

Use of handmade roof tiles, made with genuine natural materials comes with preconceptions of highly skill based work. To help with the installation our roof tiles are designed with the installer in mind. All tiles are packaged securely, have pre drilled holes for fitting to timber roof battens and come with a complementary fitting planning.

Traditional Blends

Our carefully curated range of roofing tiles, expertly represent authentic styles, colours and textures historically found throughout the UK roofing architecture. By only using natural clays, each tile have natural variations in shape and texture which will furnish your build with a traditional and long established look.

Natural Clay Roofing Product FAQs

Are clay tile roofs environmentally friendly?

They are made from natural materials, such as clay, sand, and water, which are abundant and easily accessible. This means that they have a much lower environmental impact than other roofing materials, such as asphalt shingles or metal roofing.

How to install handmade roof tiles?

Plain tiles are laid on the battens in a 'brick bond' pattern, i.e. with the joints between them aligned with the centre of the tile above and below, and with about 3mm between the sides. This layout gives a double lap covering, (i.e. the top part of each tile is covered by two tiles, the centre of the tile of the next row and the lower part of the tile above that). All perimeter tiles should be twice nailed. Ridge and hip tiles to be secured using mortar. Each tile is laid to a gauge to give a minimum head lap of 65mm

How Are Clay Roof Tiles Made?

After being dug from the ground, the clay used to make the tiles has to be weathered for around nine months to a year.

It is then ground into fine particles with water added to make the clay workable. At this stage grog (which is previously fired clay pieces ground down) is added to help reduce shrinking, cracking and warping during the firing process. This also naturally adds texture to the tile.

Historically, handmade tiles would been hand thrown into the mould before being finished. However, nowadays they are more often mechanically pressed either by hand or by using a hydraulic press to ensure a more consistent density and to speed up production.

The roof tiles are then handled and dried in several ways to create the different character variations of shape and colour. The shape is created either by hand or machine and the colour can be varied by adding different oxides. For example, manganese oxide fires to a darker colour.

Temperature variations within the kiln will also lead to variations in colour, with a higher temperature resulting in a darker tile.

How to choose the correct roof tile?

It is recommended that tiles are mixed from at least three crates to allow for variations within, and between, batches. Laying a roof using tiles picked from sequential crates (without mixing them) could result in pronounced stripes or blocks of colour on the finished roof.

The density of any roof tile is important as the denser the product, the less water it will absorb, which in turn means the tile is less susceptible to frost damage. It’s important to check that your roof tiles have been tested to BSEN 539-2:2013 (Determination of Frost Resistance) as a poor-quality tile could lead to expensive repairs or, at worst, a complete re-roof.

A handmade clay roof tile will typically cost up to 50% more than its machine-made counterpart but will in return offer more shape, texture and colour variation. The benefits of a handmade clay tile are all in the aesthetic and for period properties and those of character there really is no alternative.

Have you started a new project and looking for just the right tile? Give us a call to talk to one of our experts who can advise you on just the right rile for your project.

How many handmade clay tiles per m2?

The number of handmade clay tiles needed per square meter depends on the size of the tiles, the roof's pitch, and other factors. Our Heritage tiles have a covering capacity of 60 tiles per square meter and a minimum pitch of 45°

How many machine made clay tiles per m2?

The number of machine made clay tiles needed per square meter depends on the size of the tiles, the roof's pitch, and other factors. Our Heritage tiles have a covering capacity of 60 tiles per square meter and a minimum pitch of 45°

What is the life expectancy of a clay tile roof?

Tile roofs are typically the most common type of roofing, with the most popular types being clay roof tiles and concrete roof tiles. Especially since these materials can expect to last for at least 50-60 years. Though clay tiles have a lifespan commonly set by manufacturers at around 30 years.

How long with a pantile last?

Both Roman tiles and traditional pantile tiles are normally made from clay, but as with all natural materials they are prone to damage. The material itself can produce a roof that lasts for a very long time, sometimes in excess of the estimates, which are around 50 years.

How many pantiles per SQM?

Number of tiles per m2~ 16. Weight per tile ~ 2.5 kg.

What is the minimum pitch for a pantile?

Modern pantiles are also extremely versatile, they can be used on low-pitch roofs, where they'll comfortably sit on structures with a pitch as low as 12.5°.

How to get a Free Roof Tile Match?

There are several ways that you can get a free roof tile matching services, including:

- By Email

- Filling in our online form

- Project Site Visit

- Visit our Clay Tile Showroom

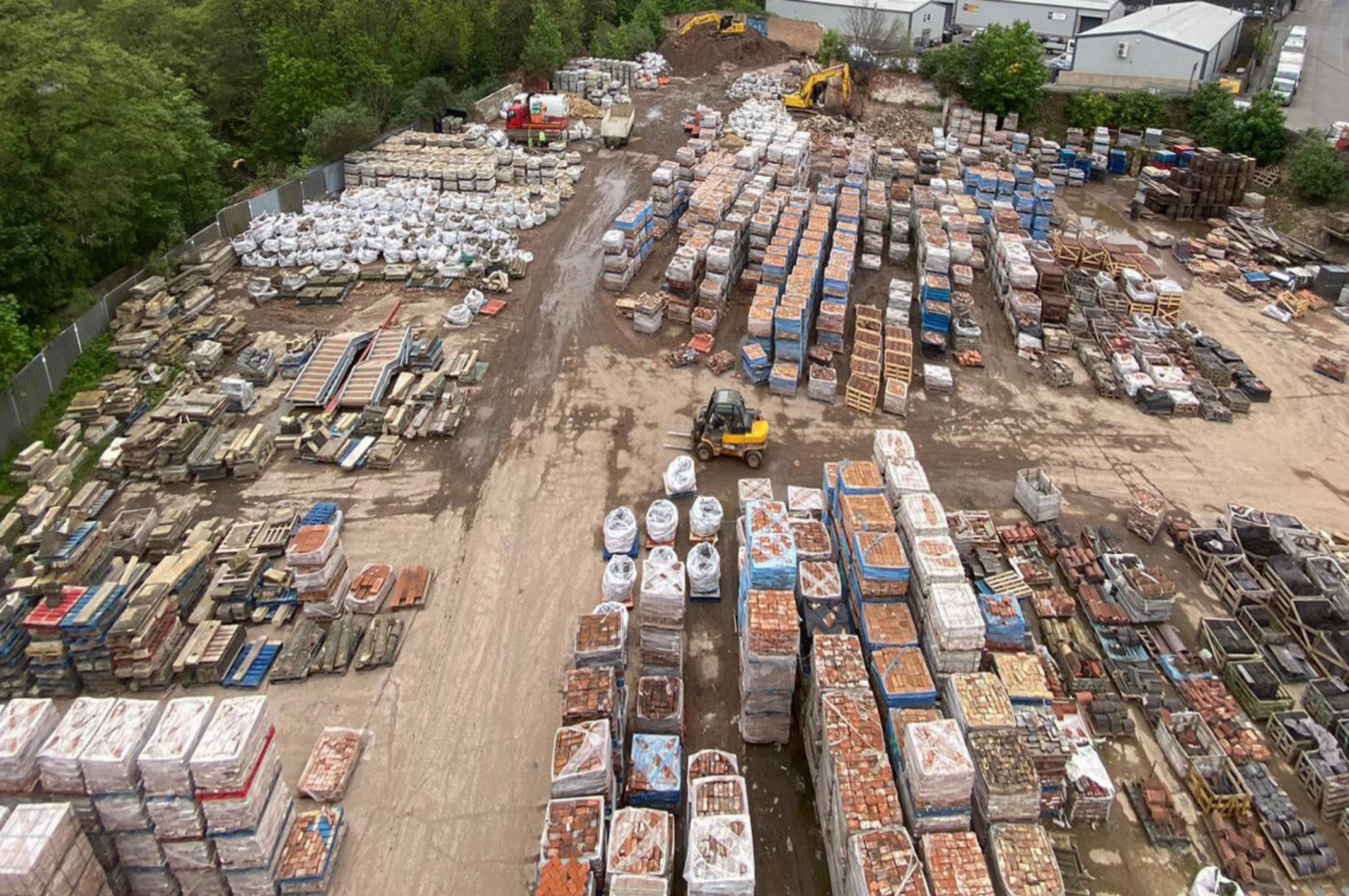

The Heritage Imperial Brick Yard provides a free and easy roof tile matching service in just a few simple steps. Our team of friendly and knowledgeable staff offer a comprehensive service delivered with the most extensive knowledge in the area.

How to order a Roof Tile Samples?

Order via Product Page

On the specific product page, to the right of the product image there is an 'Order Sample' Button. Click the button to order your sample online.

Order via Email

Simply email our sales team your project requirements and specific product you wish to order a sample.

Visit Us

If you are close by or wish to see our full range, why not come and visit us at our bespoke Brick Centre? and take samples away free of charge.

Download the Brick Catalogue

Our catalogue of curated traditional clay bricks contains the latest collection of colours and textures, produced using modern machinery and traditional manufacturing methods.